DTG Printer Quality: 4 Questions to Ask

The choice of a DTG printer for your t-shirt business should not be difficult, you just have to ask the right questions.

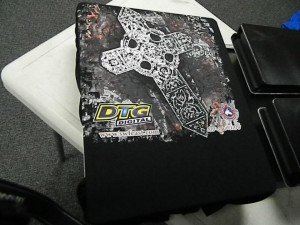

This demonstration of the M2 Direct to Garment Printer at a trade show will give you a quick idea of the parts you’ll be asking questions about.

Your DTG printer will be the heart of your direct to garment custom tee shirt printing business. Take your time with selecting the right one and use the guidelines below.

More than anything else, the best DTG printer systems features a design specifically for digital garment printing. At a minimum, printers should include: good white ink management (such as the “DTG” printer brand with the WIMS White Ink Management System), pressurized CMYK ink feed re-circulation system, extended print areas, automated head cleaning, and ink mist removal.

Direct to garment printers, also called DTG printers must be engineered specifically to print on garments and fully address the shortcomings of first and second generation machines or inkjet printers repurposed for textile printing.

4 Questions about DTG Printer Specifications

When shopping for a DTG printer for your direct to garment business, you will find yourself facing a huge variety of technical specifications. Four essential things you should ask when comparing printers:

- Does the DTG printer have a re-purposed inkjet printing system, or is it designed for garment printing from the ground up?

- What are per t-shirt printing costs: ink, pretreatment, other supplies and maintenance?

- What are reasonable estimates of print times and productivity? If the RIP software of a DTG printer requires constant tweaking to get a customer’s face ready for printing, you must remember that in estimating turnaround times.

- Can it do high quality dark garment printing? or Will it print on black tees?

Knowing the Needs of Your Business

Deciding on a DTG printer can be complicated, but asking the right questions can make the process a lot easier. The four questions above are non-negotiable, but your search for a DTG printer should also start by answering a few things about your own business goals:

- Who are your target customers?

- What do you want to be your daily amount of prints?

- Will you be using the printer for “while-you-wait” clients or will you be taking orders for delivery?

- Which is more urgent, speed or equipment cost?

- Are you looking for a niche market, such as oversize prints, beach towels, collared or sleeve prints, artwork on canvas, and so on?

- How often will you be using the DTG printer?

If your feel your direct to garment business will be primarily one-offs or single runs, with the occasional multiple quantity, you may want to consider DTG printers like the DTG Viper or the M-Series DTG Printers which are suitable for fast production of 1-8 garments at a time.

A business model geared toward larger production needs a DTG printer that is engineered exclusively for high volume production.

DTG Printer Features Important To Garment Decorators

Quantity is a significant concern when deciding on a DTG printer, but it is not the only one. There are some features that all garment decorators should look at:

- Features that are for the specific challenges of printing on garments with textile inks (like white ink management systems, RIP software and flexibility of the platen systems).

- Support and training provided by the distributor or retailer. Will they remain available to respond to your questions, give advice or troubleshoot if problems occur?

- Performance of the DTG printer. This is the bottom line for your direct to garment printing business; do the prints that come from the DTG printer look good, wash well and last long.

Welcome to the “Dark” Side of Garment Printing

In a competitive marketplace, direct to garment printers have to meet the needs of today’s customer. To have the best products available means you will be printing on all types of shirts, in a variety of styles and colors. This means your DTG printer should be ready for all garments, including dark t-shirts.

There are certain challenges to dark garment printing, which can limit the products a shop can ultimately provide. Your success on darks rests on white ink; a base coat of white is what makes images stand out on dark garments, without wading.

Many machines (like Brother Brand Printers) have difficulty printing the white ink needed for direct to garment printing on darks. Businesses with the right DTG printer to handle white ink and can master the art of dark garment printing may reach up to three-quarters of their orders on darks. That is a lot of traffic to turn down, just because you don’t have the proper equipment!

DTG Brand printers are designed with WIMS, to deliver the best results on both light and dark garments.

With The Right Help, Your Decision Can Be Easy!

Like any significant business decision, the search for the right DTG printer might take some time. You will also need to budget a period to learn to use the printer you finally get. Not surprisingly, the best DTG printers are often the easiest to master, sometimes only taking a day or two to learn. With the right information and advice, purchasing the right printer can be a decision that you will never regret.

The specific DTG Printers we used as examples, and our favorites, are made by ColDesi Inc. They have everything you need to get a direct to garment printing company started, from DTG printers and accessories and tools like heat presses and pretreatment machines.