Is Direct to Garment Printing Dead?

TIs Garment Printing Dead? he Direct to Garment Printers (or DTG) has been an integral part of the mass customization movement since it began some 10 years ago. With improvements in t-shirt transfer technologies, they’re causing us to ask: Is there really anything special about our printers?

A few months ago I was discussing this very topic with a friend when he brought up something called “DTPGMC” — or Delivering Products Quickly And Cost Effectively! Now that’s got my attention because if successful will surely change how businesses do business forever…

The Promise of DTG Printing..

The arrival of direct-to-garment (DTG) printers was met with great promise as they could produce small quantities, high-resolution prints on demand. This came at a time when most shirts were screen printed or silk-screened and this new technology promised better quality without any setup costs!

Screen printing required you to create multiple screens for multiple colors through a multi-step process, accumulating expenses along the way, before you print your first shirt.

DTG means what it says; you basically load a blank shirt into the machine and print directly onto it using water-based ink in an ink-jet process.

What was once the domain of print media is now moving into our clothing. With new technology, designers can create intricate designs for short-run production and even make bespoke garments with full-color printing on demand from companies like Zazzle or Cafe Press

In recent years there has been an influx in competition as more traditional methods struggle to keep up but one company that stands out in this trend? Is Garment Printing Dead?

OKI 920WT White Toner Printer

OKI Data has been around for a generation, but their white toner printer technology is bringing them into the custom t shirt market for the first time. Known for its commercial laser printers, industrial printers and color LED, you’ll find office managers and graphics print houses all over the country with an OKI brand in their printing stables, and they’ve brought that quality and workhorse reputation into this new market.

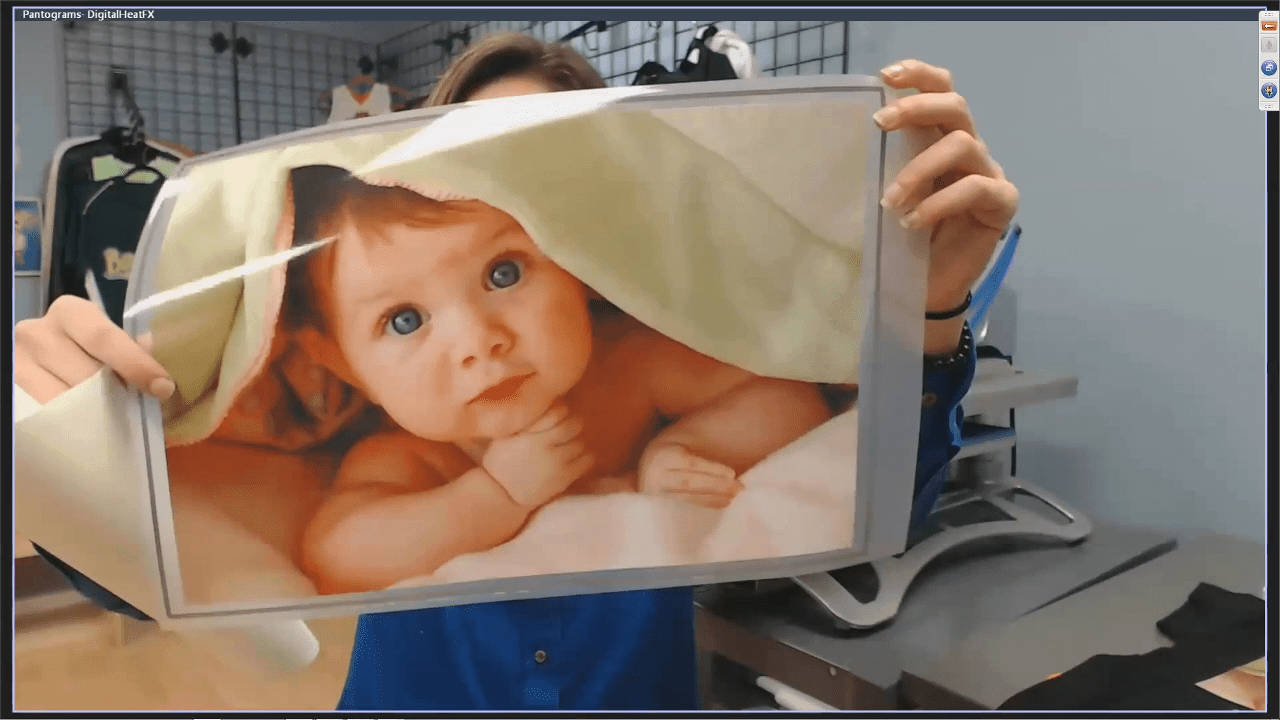

The OKI 920WT (part of this Digital HeatFX System) is a color LED (like a laser) printer that uses toners instead of ink. The magic for custom t shirt businesses is in several different areas:

Instead of CMYK toner to make a color image it uses CMYW. Cyan, Magenta, Yellow and BLACK vs. Cyan, Magenta, Yellow and WHITE.

Why is that important? Because you can make a color t shirt transfer with any color printer, but you can only apply it onto a light colored garment. Without the white layer, if you put a red design on a black t shirt, the color will look pink, for example.

It uses Toner instead of Ink. When you list out any of the drawbacks of garment printing with DTG, the fact that it uses liquid ink is rarely brought up.. mostly because that’s what all DTG printers use, as does screen printing. Liquid inks travel through tubes and squirt out through the ink jets onto the t-shirt.

Read this article about printing black with the OKI920WT White Toner Printer

Why is that important? Because ink systems require daily maintenance, weekly maintenance, and monthly maintenance. They have filters and lines that can clog and print heads that can clog. If the maintenance is ignored at all, then those clogs become costly.. thousands of dollars costly.

You Make MORE Things. The primary limitation of direct-to-garment printing has always been that the ink needs a natural fiber to adhere to. It needs something to bond with so the print lasts through washes and over time. Not so with the t-shirt transfers made by the OKI 920WT White Toner Printer!

Why is that important? Because you can now sell customized polyester shirts, customized sportswear, jerseys, nylon jackets, and a lot more promotional products than with direct garments.

It was Cheap. Compared to Direct to Garment printers at $15-$25K, the Digital HeatFX system, which is based on the OKI 920WT White Toner Printer, can be had for as little as $8,000 ( with shipping) and usually tops out at under $11K including a top of the line heat press Is Garment Printing Dead?

Why Use Direct to Garment Printing?

So IS direct to garment printing really DEAD?

No. Of course not. There are a few differences that make direct to garment printers the obvious choice for some businesses.

Print Size – If you haven’t noticed, there are a lot of XL, XXL, XXXL, and even larger t-shirts, hoodies, and other apparel items out there. The M2 direct to garment printer from ColDesi is one of the best DTG printers on the market and has one of the largest printing fields on the market as well at almost 18”x24” as compared to the suddenly small sounding 10”x16” printable area on a white toner printer. That’s 160 square inches vs 432 square inches of print! If you want to print big, direct to garment is the way to go. Learn more about DTG ROI here: http://www.dtgprintermachine.com/dtg-printer-roi

“Hand” – That’s what people in the business call how the garment feels to the touch. On a light colored shirt, like a white cotton tee, it is virtually impossible to feel a good direct to garment print. On a dark shirt you can feel it more because of the white underbase, but it’s still much software to the touch than a t shirt transfer made with the OKI or the Digital HeatFX system.

Cost per Print – One of the drawbacks AND advantages to using a t-shirt transfer system is that you are using a single sheet of “paper”, so the cost of doing a print of a certain size is exactly the same every time. Easy to quote and track your profits. The downside is that if someone just wants a single 4×6” print you’ll need to charge them for an entire page, and your cost is the same for a light or a dark shirt. With direct to garment, you have much more control; since you’re printing directly onto the shirt if you print a 4×6” graphic that’s no problem. AND if you print it on a light-colored garment you use no white ink so your cost is about ½ of what it would be on a dark one. In this case, DTG Printers clearly win.

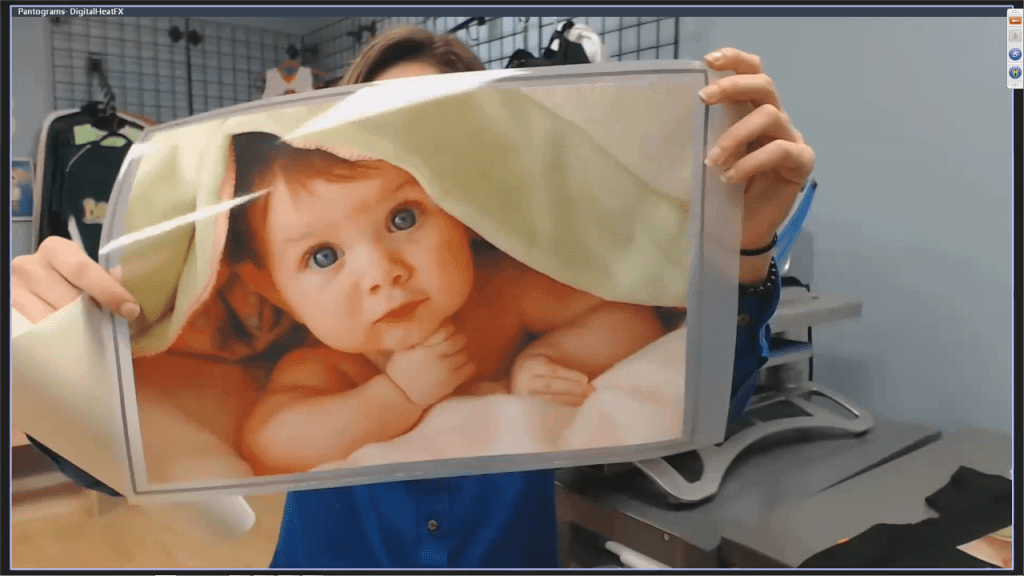

Pretty, pretty prints – you can get some good-looking prints with the OKI printer, especially using the combo that Digital HeatFX offers, but there’s nothing that will reproduce the quality, resolution, and just plain beauty of a good direct to garment print. Fade to nothing, gradient colors, and tones, it all looks superb on direct to garment.

Here’s a great video showing the quality of DTG

Prints

Printing on Canvas | Direct to Garment Printers from ColDesi from ColDesi, Inc. on Vimeo.

Conclusion

Direct to Garment is alive and well. In fact, if you read the trade magazines and attend the trade shows, it’s just getting better! Direct to Garment is coming down in price and up in capabilities. At a recent show they were demonstrating printing on dark-colored 100% polyester shirts, which would add a whole dimension to the DTG business for small shops. For larger ones, DTG Digital has announced the new M3 model direct to garment printer which will let you print up to SIX shirts at once (even 6 different designs) or one HUUUUUGGGEEEEE print. AND the M2 is coming out with a network modular approach where you can run more than one printer from a single computer – great for production.

The Good News? As t-shirt transfer technology improves, so does direct-to-garment printing – and so do our options as apparel decorators!