Comparing the Top DTF (Direct to Film) Printers

High Volume, Direct-To-Film Transfer Printers have finally arrived!

ColDesi DTF Printers are ALREADY powering some of the biggest names in customization.

And that’s because of 3 things:

High Volume

High Volume printing is on another level with DTG Printing. You can Produce hundreds of different graphics/sizes in one run or print thousands of your best-selling designs.

Expertise

There is no one that knows high volume DTF printing like ColDesi. Our R&D team is at the leading edge of productivity enhancements. And our sales and support teams are capable, knowledgeable veterans of custom apparel printing.

The TECHNOLOGY Works

Direct to film is the best way to produce high-volume custom transfers for apparel. Especially custom t-shirts.

And the Raw Machine Output (RMO) on the DTF is what makes this new technology so revolutionary. You can produce brilliant full-color prints:

- On Virtually Any Garment

- In Virtually Any Placement

- Around 10 Seconds Press Time

- Through dozens of wash cycles

It’s like nothing you’ve ever seen.

How does a DTF Printer work?

The DTF-24H2 AND DTF-24H4 produce brilliant digital transfer sheets, handling everything from single color shirt labels to left chest logos to full-size prints. The DTF printer uses PET transfer film which is translucent so you can see the design underneath the film when you later heat-press it onto the garment. The PET film has a thickness of around 0.75mm which allows for better transfer characteristics.

Check out these Videos about DTF Printers

DTF | Best Custom Hats

DTF Printer Case Study

DTF & DTG Compared

Keep reading to learn how the DTF-24H4 printer can deliver direct film transfers (DTF Transfers) better than any other DTF on the market.

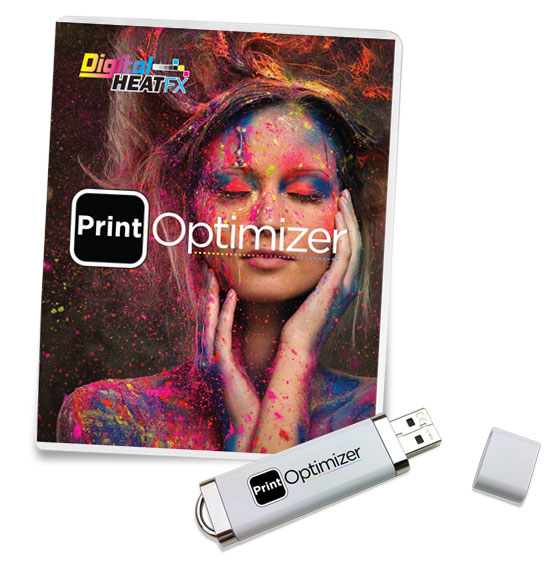

Includes Print Optimizer RIP Software

As part of a Digital HeatFX system, which includes the Print Optimizer software, you will have ultimate control over the ink laydown. If you are doing blended gradients you can dial in the color accuracy on a per-channel basis. If you are doing single color logos on white shirts, you can dial down the ink flow and put just the right amount of ink to make the shirt pop without ink waste.

High Quality Commercial Printheads

The 24H2 is a 24″ DTF printer that has a dual print head design that lays down the colors in a blend of CMYK colors with the first printhead, and then lays down the perfect amount of white underbase on top of the colors in perfect alignment so that you do not have any white peeking out. The alignment is on the film, rather than on the bumpy fabric of the shirts so it creates a crisp design edge that you can’t even get with traditional screen printing.

The 24H4 is the same size (24″ wide) but with a 4 head design that prints EVEN FASTER. So fast it includes a larger, longer dryer to accomodate the speed.

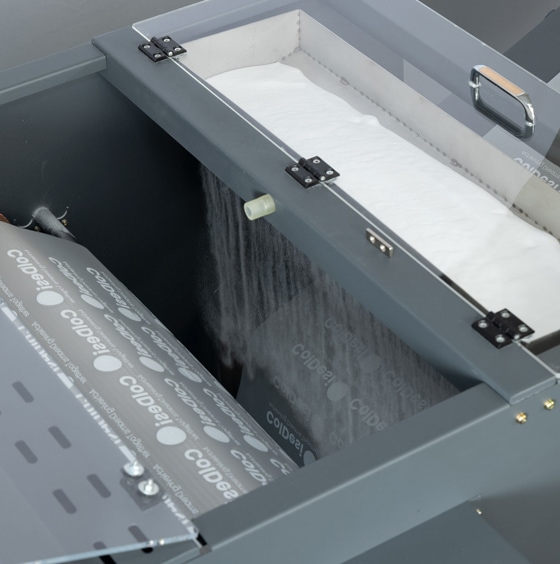

Applying the Adhesive to the Custom DTF Transfer Prints

It’s the unique powder adhesive coating that gives DTF prints their signature soft touch. Instead of thick transfer films, or vinyl’s, the Direct to Film Process has only two ingredients. The ink, and a thin coating of powered adhesive.

The soft hand of DTF is holy grail of custom apparel. It’s never been possible to get the incredible soft feel of half-tone screen printing in a transfer process. But with DTF, you get all that and more.

The DTF powder adhesive is moisture-seeking, so it draws itself into the ink of the print and chemically bonds to form a strong permanent adhesive that sticks extremely strong to both cotton and polyester fibers.

DTF 24H2

-

Speed: 45-55 Linear Feet per hour

-

Speed: 100 Full Front Transfers/hour

-

Print Optimizer Software

-

Training & Support

-

Dimensions:

Printer only: 37" x 67.5"

Applicator: 76" x 38"

Combined: 67.5" x 131"

What are the Advantages of DTF?

- Faster Machine Output than DTG or White Toner

- Prints on virtually all material types.

- Double Print Head Technology

- Separate White Ink Channels

- As Durable as Screen Printing (over 20 washes**)

- Beautiful Digital Gradients and HDR Colors

- Everything you need to get started including Training and Support.

DTF 24H4

-

Speed: 145 Linear Feet per hour

-

Speed: 300 Full Front Transfers/hour

-

Print Optimizer Software

-

Training & Support

-

Dimensions:

Printer only: 35.5" x 78"

Applicator: 43.5" x 84"

Overall: 78" x 132"

*Continental U.S. only, with approved credit. Not good with any other offer.

Machine Specifications:

The applicator should be vented outside but can be vented into an air purifier capable of handling up to 285 degrees Fahrenheit. The applicator has a 2″ hose ported out from the bottom.

The printer and applicator are shipped in crates and preassembled. The crate dimensions for the Printer are 48″x 83″x 74″ with a weight of 750 lbs. and the Powder/Dryer dimensions are 46″x 90″x 56″ with a weight of 970 lbs. The LTL delivery is to your receiving department, loading dock, or driveway. Uncrating and self-installation are the responsibility of the receiver. With the size of the DTF-24H4 system, double doors or an opening larger than 43.5″ are required. Both the printer and applicator are on casters and can easily be moved once removed from crates. The printer is 550 lbs. assembled and the Powder/Dryer is 690 lbs. Will require 3-4 people to lift over any steps or move safely.

To operate Digital Heat FX Print Optimizer with the DTF-24H4 printer, a dedicated Windows 10 PC (or greater) with an Ethernet connection is required. For best results, the PC should have a minimum of 32GB RAM and a 500GB solid-state hard drive. Due to the printer not being networkable, for networking or internet access, WiFi capabilities are necessary.

Print Speed and Productivity Differences | 2 Head vs 4 Head DTF Printers

What can you Print with the DTF Machines?

The beauty of the DTF system by Digital HeatFX is that you can store your high-quality transfers for up to 6 months or more. This allows you to keep separate your print operations and your assembly line(s).

With other technologies such as screen-printing and DTG, you must bring the garment to the printer.

Your ability to create finished goods depends on how many garment holding stations your printer has.

But with DTF, your print speed, and raw machine output of the printer his much greater. If you are printing left chest logos, for instance, and you can print 8-10 copies of the same logo in about 10 seconds. You can add as many assembly stations as you need to make the most efficient use of the incredible machine output.

DTF Works With all Kinds of Fabrics:

- Combed Cotton

- Ring Spun Cotton

- Organic Cotton

- Polyesters

- Blended Fabrics

- Poly-Cottons

- Tri-Blends

- Polyester-Spandex

DTF Transfer Printing vs Screen Printing

So, what’s making automatic screen print shops switch over to DTF Transfer Printers? The benefits are enormous:

- No Screen Mess

- Setup takes Minutes not Hours.

- No need for a Darkroom

- No Measuring and Mixing Inks to match colors.

- No Gas-Powered Belt Dryer (or Elec)

- Better Quality Prints

- No Wasted Garments due to Registration or Popped Screens.

- Takes up MUCH LESS ROOM

Mark our words here, DTF is no less than a technology revolution for the Screen-Printers. You can print up the designs for an entire order AND print up enough extra transfers for your FILL-IN orders all at once. Then you simply press the transfers on whatever garments you need. All in about 10 seconds.

If you’re in a rush, your final speed of assembly is ONLY limited by the number of heat presses you have.

Some Shops will employ dozens of skilled heat press assemblers and bagging helpers just to keep up with the raw machine output (RMO) of their DTF transfer printers.

DTF Transfer Printing vs DTG Direct to Garment

This idea of parallel assembly of the DTF Transfers to the garments is also the PRIMARY strength vs high end DTG machines like the Kornit, and Aeoon. With those machines, the machine operator is stuck standing in front of the DTG machine constantly, making sure that every shirt is perfectly flat. Most of their time is spent idle, simply waiting for the machine to print.

The DTF process is different. The print function is separate from the application function.

You don’t have to bring the shirt to the machine. Instead, you bring the image to as many shirts as you want.

Some other benefits over DTG:

- Little to NO Print Head Clogs

- No Pre-Treat Chemicals or Wetting of the shirt needed.

- No Need to DRY the shirt at all (Saves Energy)

- Lower Ink & Adhesive Cost / Compared to Ink & Pretreat

- Press times that are up to 5 TIMES FASTER than DTG

- No Need to Pre-Press

- Parallel Processing and Assembly

What can you Print with the DTF Printer?

DTF Works With all Kinds of Garments:

- T-shirts

- Polos

- Sweatshirts

- Backpacks

- Aprons

- Flags

- Sports Uniforms

- Company Dress Shirts